The quality of 200 series carbide ball end milling cutters is comparable to those of Japan and Korea, and its quality has surpassed that of famous brands in China and Taiwan.

Imported 0.2μm ultra-micron carbide material is used, which is excellent in high-speed machining of high-hardness materials with good wear resistance.

Higher surface finish when processing optical molds, especially suitable for processing high hardness materials of hardened steel within 65HRC.

Minimum diameter up to 0.1MM.

High precision tolerances and quality control.

Oil mist, trace lubrication or air cooling is recommended.

Semi-finishing and finishing.

Table for use of processed materials √well suited 〇general

|

Carbon steel Alloy steel |

Prehardenedsteel、Hardened steel |

Stainless steel |

Cast iron |

Coppe |

Aluminium |

Graphite |

Titanium alloy |

Heat resistant alloy |

Plastics |

|||

|

40HRC |

50HRC |

55HRC |

65HRC |

|||||||||

|

〇 |

〇 |

√ |

√ |

√ |

〇 |

〇 |

〇 |

〇 |

〇 |

|||

|

R≤3 R±0.005 R>3 R±0.008 |

||||

|

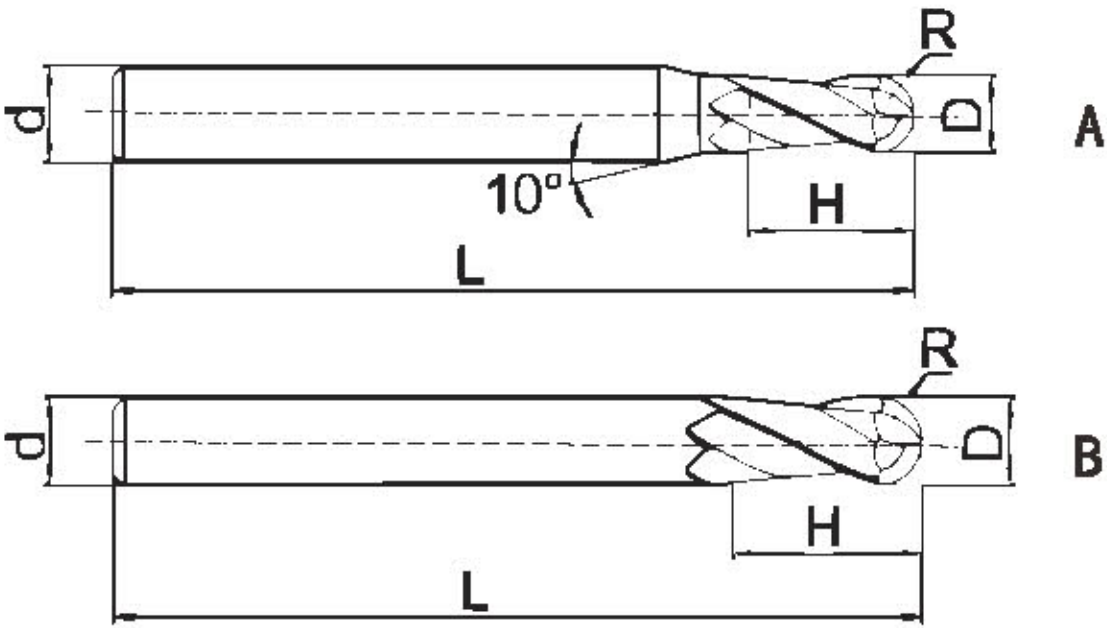

radius R |

Blade length H |

Stem diameter d |

Total length L |

Illustration |

| R0.5 | 1.5 | 4D | 50L | A |

| R0.75 | 2 | 4D | 50L | A |

| R1 | 3 | 4D | 50L | A |

| R1.25 | 3.5 | 4D | 50L | A |

| R1.5 | 4 | 3D | 50L | B |

| R1.5 | 4 | 4D | 50L | A |

| R2 | 6 | 4D | 50L | B |

| R1 | 3 | 6D | 50L | A |

| R1.5 | 4 | 6D | 50L | A |

| R2 | 6 | 6D | 50L | A |

| R2.5 | 7 | 6D | 50L | A |

| R3 | 9 | 6D | 50L | B |

| R3 | 9 | 6D | 75L | B |

| R3 | 9 | 6D | 100L | B |

| R4 | 12 | 8D | 60L | B |

| R4 | 12 | 8D | 75L | B |

| R4 | 12 | 8D | 100L | B |

| R4 | 12 | 8D | 150L | B |

| R5 | 15 | 10D | 75L | B |

| R5 | 15 | 10D | 100L | B |

| R5 | 15 | 10D | 150L | B |

| R6 | 18 | 12D | 75L | B |

| R6 | 18 | 12D | 100L | B |

| R6 | 18 | 12D | 150L | B |

| R8 | 24 | 16D | 100L | B |

| R8 | 24 | 16D | 150L | B |

person: Mr. Gong

Tel: +86 0769-82380083

Mobile phone:+86 15362883951

Email: info@jimmytool.com

Website: www.jimmytool.com