The 400 series carbide end mills offer excellent performance and cost-effectiveness.

Selected 0.4μm ultra-fine grain high-quality cemented carbide material, with excellent wear resistance and anti-chipping performance, can meet the complex working conditions, for machining 35HRC-52HRC materials.

Special tool design with high rigidity performance material can get good anti-vibration effect and make the service life of end mill longer.

High precision tolerance and quality control.

The use of coolant and oil-containing cutting fluid is recommended.

Roughing and finishing.

Table for use of processed materials √well suited 〇general

|

Carbon steel Alloy steel |

Prehardenedsteel、Hardened steel |

Stainless steel |

Cast iron |

Coppe |

Aluminium |

Graphite |

Titanium alloy |

Heat resistant alloy |

Plastics |

|||

|

40HRC |

50HRC |

55HRC |

65HRC |

|||||||||

|

√ |

√ |

√ |

〇 |

〇 |

√ |

〇 |

〇 |

〇 |

〇 |

|||

| D≤12 0~-0.02 12<D 0~-0.03 | ||||

| blade diameter D |

blade length H |

shank diameter d |

total length L |

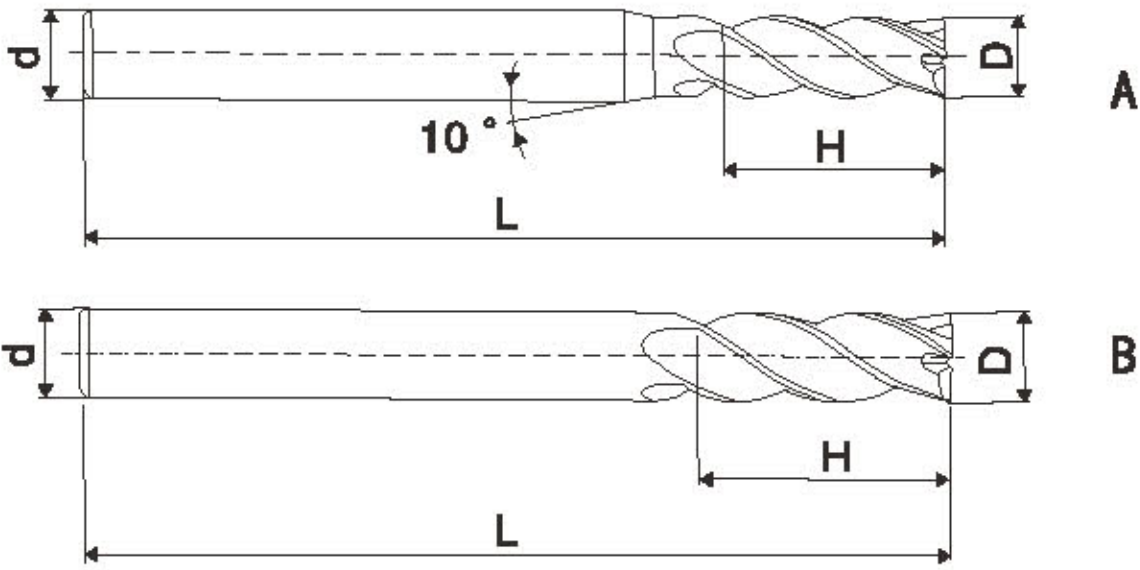

illustration |

| 1.0 | 3 | 4D | 50L | A |

| 1.5 | 4 | 4D | 50L | A |

| 2.0 | 5 | 4D | 50L | A |

| 2.5 | 8 | 4D | 50L | A |

| 3.0 | 8 | 3D | 50L | B |

| 3.0 | 8 | 4D | 50L | A |

| 3.5 | 10 | 4D | 50L | A |

| 4.0 | 10 | 40 | 50L | B |

| 4.5 | 10 | 5D | 50L | A |

| 5.0 | 13 | 6D | 50L | A |

| 5.0 | 20 | 6D | 75L | A |

| 5.5 | 13 | 6D | 50L | A |

| 6.0 | 15 | 6D | 50L | B |

| 6.0 | 20 | 6D | 75L | B |

| 6.0 | 20 | 6D | 100L | B |

| 7.0 | 20 | 8D | 60L | A |

| 8.0 | 20 | 8D | 60L | B |

| 8.0 | 25 | 8D | 75L | B |

| 8.0 | 25 | 8D | 100L | B |

| 9.0 | 20 | 10D | 75L | A |

| 10.0 | 25 | 10D | 75L | B |

| 10.0 | 30 | 10D | 100L | B |

| 10.0 | 30 | 10D | 150L | B |

| 11.0 | 25 | 12D | 75L | A |

| 12.0 | 30 | 12D | 75L | B |

| 12.0 | 35 | 12D | 100L | B |

| 12.0 | 35 | 12D | 150L | B |

| 14.0 | 35 | 14D | 75L | B |

| 16.0 | 45 | 16D | 100L | B |

| 16.0 | 50 | 16D | 150L | B |

| 20.0 | 45 | 20D | 100L | B |

person: Mr. Gong

Tel: +86 0769-82380083

Mobile phone:+86 15362883951

Email: info@jimmytool.com

Website: www.jimmytool.com