Excellent performance and cost-effective. Comparable to the quality of Europe, America and Japan.

Selection of 0.2μm imported ultra-micro carbide materials, high-speed processing of high hardness material life longer.

Higher surface finish when processing optical moulds, better wear resistance when processing high hardness materials.

the smallest diameter can be done diameter 0.1MM.

Special tool design, high precision tolerance and quality control.

Oil mist, trace lubrication or air cooling is recommended.

Semi-finishing and finishing.

| Table of applicable milling materials | √ very suitable | ⭕general | |||||||||||

| carbon steel | Pre hardened steel, hardened steel | stainless steel | cast iron | copper alloy | aluminum alloy | graphite | titanium alloy | High-temperature alloy | plastics | ||||

| alloy steel | chisel tool steel | 40HRC | 50HRC | 55HRC | 65HRC | ||||||||

| √ | √ | √ | √ | 〇 | 〇 | 〇 | |||||||

| R<0.5 ±0.003 R≥0.5 ±0.005 | |||||

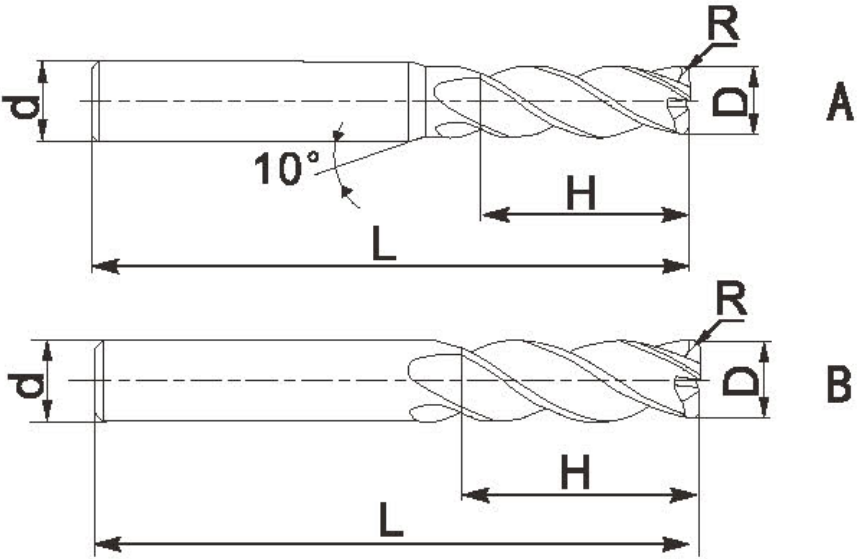

| Blade diameter D | Rangular radius R | blade length H |

Handle diameter d |

Total length L |

illustration |

| 1.0 | 0.1 | 2 | 4D | 50L | A |

| 1.0 | 0.2 | 2 | 4D | 50L | A |

| 1.5 | 0.1 | 3 | 4D | 50L | A |

| 1.5 | 0.2 | 3 | 4D | 50L | A |

| 1.5 | 0.3 | 3 | 4D | 50L | A |

| 2.0 | 0.1 | 4 | 4D | 50L | A |

| 2.0 | 0.2 | 4 | 4D | 50L | A |

| 2.0 | 0.3 | 4 | 4D | 50L | A |

| 2.5 | 0.2 | 5 | 4D | 50L | A |

| 2.5 | 0.5 | 5 | 4D | 50L | A |

| 3.0 | 0.1 | 6 | 3D | 50L | B |

| 3.0 | 0.2 | 6 | 3D | 50L | B |

| 3.0 | 0.3 | 6 | 3D | 50L | B |

| 3.0 | 0.5 | 6 | 3D | 50L | B |

| 3.0 | 0.1 | 6 | 4D | 50L | A |

| 3.0 | 0.2 | 6 | 4D | 50L | A |

| 3.0 | 0.3 | 6 | 4D | 50L | A |

| 3.0 | 0.5 | 6 | 4D | 50L | A |

| 4.0 | 0.2 | 8 | 4D | 50L | B |

| 4.0 | 0.3 | 8 | 4D | 50L | B |

| 4.0 | 0.5 | 8 | 4D | 50L | B |

| 5.0 | 0.3 | 10 | 6D | 50L | A |

| 5.0 | 0.5 | 10 | 6D | 50L | A |

| 6.0 | 0.2 | 12 | 6D | 50L | B |

| 6.0 | 0.3 | 12 | 6D | 50L | B |

| 6.0 | 0.5 | 12 | 6D | 50L | B |

| 6.0 | 1.0 | 12 | 6D | 50L | B |

| 6.0 | 0.2 | 12 | 6D | 75L | B |

| 6.0 | 0.5 | 12 | 6D | 75L | B |

| 6.0 | 1.0 | 12 | 6D | 75L | B |

| 6.0 | 0.2 | 12 | 6D | 100L | B |

| 6.0 | 0.5 | 12 | 6D | 100L | B |

| 6.0 | 1.0 | 12 | 6D | 100L | B |

| 8.0 | 0.2 | 16 | 8D | 60L | B |

| 8.0 | 0.5 | 16 | 8D | 60L | B |

| 8.0 | 1.0 | 16 | 8D | 60L | B |

| 8.0 | 0.2 | 16 | 8D | 75L | B |

| 8.0 | 0.5 | 16 | 8D | 75L | B |

| 8.0 | 1.0 | 16 | 8D | 75L | B |

| 8.0 | 0.2 | 16 | 8D | 100L | B |

| 8.0 | 0.5 | 16 | 8D | 100L | B |

| 8.0 | 1.0 | 16 | 8D | 100L | B |

| 10.0 | 0.5 | 20 | 10D | 75L | B |

| 10.0 | 1.0 | 20 | 10D | 75L | B |

| 10.0 | 0.5 | 20 | 10D | 100L | B |

| 10.0 | 1.0 | 20 | 10D | 100L | B |

| 10.0 | 0.5 | 20 | 10D | 150L | B |

| 10.0 | 1.0 | 20 | 10D | 150L | B |

| 12.0 | 0.5 | 24 | 12D | 75L | B |

| 12.0 | 1.0 | 24 | 12D | 75L | B |

| 12.0 | 0.5 | 24 | 12D | 100L | B |

| 12.0 | 1.0 | 24 | 12D | 100L | B |

| 12.0 | 0.5 | 24 | 12D | 150L | B |

| 12.0 | 1.0 | 24 | 12D | 150L | B |

| 16.0 | 0.5 | 32 | 16D | 100L | B |

| 16.0 | 1.0 | 32 | 16D | 100L | B |

| 16.0 | 0.5 | 32 | 16D | 150L | B |

| 16.0 | 1.0 | 32 | 16D | 150L | B |

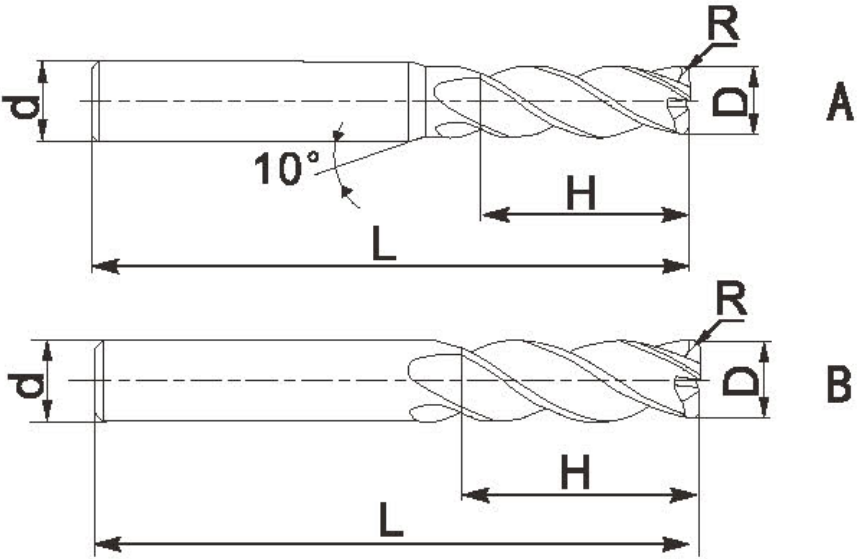

| R<0.5 ±0.003 R≥0.5 ±0.005 | |||||

| flute diameterD | R angle radiusR |

flute length H |

shank diameter d |

total length L |

illustration |

| 1.0 | 0.1 | 2 | 4D | 50L | A |

| 1.0 | 0.2 | 2 | 4D | 50L | A |

| 1.5 | 0.1 | 3 | 4D | 50L | A |

| 1.5 | 0.2 | 3 | 4D | 50L | A |

| 1.5 | 0.3 | 3 | 4D | 50L | A |

| 2.0 | 0.1 | 4 | 4D | 50L | A |

| 2.0 | 0.2 | 4 | 4D | 50L | A |

| 2.0 | 0.3 | 4 | 4D | 50L | A |

| 2.5 | 0.2 | 5 | 4D | 50L | A |

| 2.5 | 0.5 | 5 | 4D | 50L | A |

| 3.0 | 0.1 | 6 | 3D | 50L | B |

| 3.0 | 0.2 | 6 | 3D | 50L | B |

| 3.0 | 0.3 | 6 | 3D | 50L | B |

| 3.0 | 0.5 | 6 | 3D | 50L | B |

| 3.0 | 0.1 | 6 | 4D | 50L | A |

| 3.0 | 0.2 | 6 | 4D | 50L | A |

| 3.0 | 0.3 | 6 | 4D | 50L | A |

| 3.0 | 0.5 | 6 | 4D | 50L | A |

| 4.0 | 0.2 | 8 | 4D | 50L | B |

| 4.0 | 0.3 | 8 | 4D | 50L | B |

| 4.0 | 0.5 | 8 | 4D | 50L | B |

| 5.0 | 0.3 | 10 | 6D | 50L | A |

| 5.0 | 0.5 | 10 | 6D | 50L | A |

| 6.0 | 0.2 | 12 | 6D | 50L | B |

| 6.0 | 0.3 | 12 | 6D | 50L | B |

| 6.0 | 0.5 | 12 | 6D | 50L | B |

| 6.0 | 1.0 | 12 | 6D | 50L | B |

| 6.0 | 0.2 | 12 | 6D | 75L | B |

| 6.0 | 0.5 | 12 | 6D | 75L | B |

| 6.0 | 1.0 | 12 | 6D | 75L | B |

| 6.0 | 0.2 | 12 | 6D | 100L | B |

| 6.0 | 0.5 | 12 | 6D | 100L | B |

| 6.0 | 1.0 | 12 | 6D | 100L | B |

| 8.0 | 0.2 | 16 | 8D | 60L | B |

| 8.0 | 0.5 | 16 | 8D | 60L | B |

| 8.0 | 1.0 | 16 | 8D | 60L | B |

| 8.0 | 0.2 | 16 | 8D | 75L | B |

| 8.0 | 0.5 | 16 | 8D | 75L | B |

| 8.0 | 1.0 | 16 | 8D | 75L | B |

| 8.0 | 0.2 | 16 | 8D | 100L | B |

| 8.0 | 0.5 | 16 | 8D | 100L | B |

| 8.0 | 1.0 | 16 | 8D | 100L | B |

| 10.0 | 0.5 | 20 | 10D | 75L | B |

| 10.0 | 1.0 | 20 | 10D | 75L | B |

| 10.0 | 0.5 | 20 | 10D | 100L | B |

| 10.0 | 1.0 | 20 | 10D | 100L | B |

| 10.0 | 0.5 | 20 | 10D | 150L | B |

| 10.0 | 1.0 | 20 | 10D | 150L | B |

| 12.0 | 0.5 | 24 | 12D | 75L | B |

| 12.0 | 1.0 | 24 | 12D | 75L | B |

| 12.0 | 0.5 | 24 | 12D | 100L | B |

| 12.0 | 1.0 | 24 | 12D | 100L | B |

| 12.0 | 0.5 | 24 | 12D | 150L | B |

| 12.0 | 1.0 | 24 | 12D | 150L | B |

| 16.0 | 0.5 | 32 | 16D | 100L | B |

| 16.0 | 1.0 | 32 | 16D | 100L | B |

| 16.0 | 0.5 | 32 | 16D | 150L | B |

| 16.0 | 1.0 | 32 | 16D | 150L | B |

person: Mr. Gong

Tel: +86 0769-82380083

Mobile phone:+86 15362883951

Email: info@jimmytool.com

Website: www.jimmytool.com